|

|

Post by joatmoniac on May 9, 2016 19:01:44 GMT

I have seen a lot of freely available plans that you can download to print out your miniatures on a 3D printer. I don't own one, but was wondering if there was anyone here that had any experience with them. It seems really cool, and given that the plans are free it would only cost material, but again with little experience I have no idea if that is cost effective, or just really cool.

Just tossing it out to the collective hive mind to see if anyone has experience with the topic.

|

|

|

|

Post by catcharlie on May 9, 2016 23:04:05 GMT

I have not but I'm really interested, if I could afford a 3d printer I would so be making a ****-ton of miniatures, If somebody wants to buy me a 3d printer I'd be happy to test it out. ;D

I one saw a link to files of a very large collection of War hammer 40k minis, though that was in much murkier waters of the internet.

|

|

Samuel Wise

Demigod

Ready to Help...

Ready to Help...

Posts: 989

Favorite D&D Class: Warlock

Favorite D&D Race: Mousefolk

|

Post by Samuel Wise on May 10, 2016 0:27:36 GMT

Now that sounds amazing, I am going to see if I can build some miniatures in my CAD program, for 3D Printing. Who knows, the program can't do humans all that well, I'll see what happens. If only my University had one... should get a bigger school.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 10, 2016 4:04:26 GMT

I requested a few miniatures from a friend with a printer. They didn't turn out very good, but I suspect there's some variation in the quality of the final product based on the quality of the printer (and probably the material used).

First thing, they came out with a lot of burrs and other abnormalities that required careful removal with a razor/hobby knife. Second, smaller parts were more fragile and prone to snapping off than you'd expect with cast miniatures.

Still, they were cheap, about $1 in material each. We used them for my LoL based game, and it was easy enough to find models for the characters (Galio, Ezreal, Teemo) we used.

Briefly, I found 3d-printed minis to be low quality but serviceable. YMMV

|

|

|

|

Post by joatmoniac on May 10, 2016 17:00:55 GMT

I suspect there's some variation in the quality of the final product based on the quality of the printer (and probably the material used). This has been my concern with the idea. If I pay enough for the printer and materials would I stray close to the original cost of a miniature? The only thing is that you can go ahead and make whatever miniature that you want as long as you can find, or make, the design for it. After looking for a couple minutes it appears that it is just as easy to pay 300 as it is to pay 3000 for a 3D printer, haha. I think I will approach this the same way I do swimming pools, the best pool is someone else's pool. |

|

Samuel Wise

Demigod

Ready to Help...

Ready to Help...

Posts: 989

Favorite D&D Class: Warlock

Favorite D&D Race: Mousefolk

|

Post by Samuel Wise on May 10, 2016 21:54:40 GMT

I suspect there's some variation in the quality of the final product based on the quality of the printer (and probably the material used). This has been my concern with the idea. If I pay enough for the printer and materials would I stray close to the original cost of a miniature? The only thing is that you can go ahead and make whatever miniature that you want as long as you can find, or make, the design for it. After looking for a couple minutes it appears that it is just as easy to pay 300 as it is to pay 3000 for a 3D printer, haha. I think I will approach this the same way I do swimming pools, the best pool is someone else's pool. Keep in mind that it also depends on the size of miniatures you want to make. A cheap printer may be terrible at making regular 6" figures, but could do a good job at 12" figures. If you are doing massive pieces, like castle walls, a cheap printer would be more than fine. Not much else to say, but it is an interesting point to think about. geekandsundry.com/artist-releases-300-printable-dd-miniature-patterns-for-free/ |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 11, 2016 0:05:56 GMT

Someone else's pool, indeed! Hey, if you have nieces or nephews, tell them how awesome 3d printers are and make them bug their parents til they buy one.

|

|

|

|

Post by Tesla Ranger on May 21, 2016 16:01:12 GMT

I have a small 3D printer I frequently use for work. It's one of a handful of printers that were hypothetically meant to bring the technology to a routine consumable level. When I picked up my M3D they were going for about $350 (I think they're closer to $450 now) but I snagged it because it could print PLA and ABS (the two common types of filament), had a .5 micron resolution, and a pretty small footprint. The whole thing is an 8" cube so I can fit it easily enough on my desk.

I know the fellow's released 300 free mini models and I think that's fantastic. I'm sure eventually I'll get around to downloading some and trying them out. That said, I don't think 3D printing minis is going to become particularly commonplace. My ~$500 printer makes prints that are more functional than decorative and despite being advertised as being for the layperson it still requires a lot of fiddling to work. If the conditions aren't -just- right, if there's too much tension on the filament, if the print bed isn't sticky enough (or if it's too sticky), if there's any kind of give or slack in the gears or bands, then your print isn't coming out at all. On top of that, there's a lot to learn about how the digital models themselves are constructed so that they'll print cleanly. Anything with wings or any other outstretched limb is never not going to be an absolute PITA to print on a conventional 3D printer.

Even when everything lines up, most prints still need some cleaning up if you want them to look pretty. If you want consistently good prints, prints detailed enough to be minis, then you're probably looking at a $2,000-4,000 printer (MakerBot or the like). The smaller, less expensive printers are fine for tools and parts but probably won't yield results a mini-printer would be satisfied with.

That said, HeroForge does a pretty great job of printing custom minis on demand. $15 gets you a low resolution plastic mini (really easy to paint) and $25 gets you a perfectly detailed resin mini (reported as being more fragile but I haven't had a problem so far). HeroForge is a division of Shapeways which has a really solid reputation in the 3D printing industry. For myself, I might try printing out a few NPCs or boss-types on my little printer but I suspect I'll always be ordering my PCs from HeroForge if I don't already have a good mini.

|

|

|

|

Post by Tesla Ranger on May 21, 2016 16:17:50 GMT

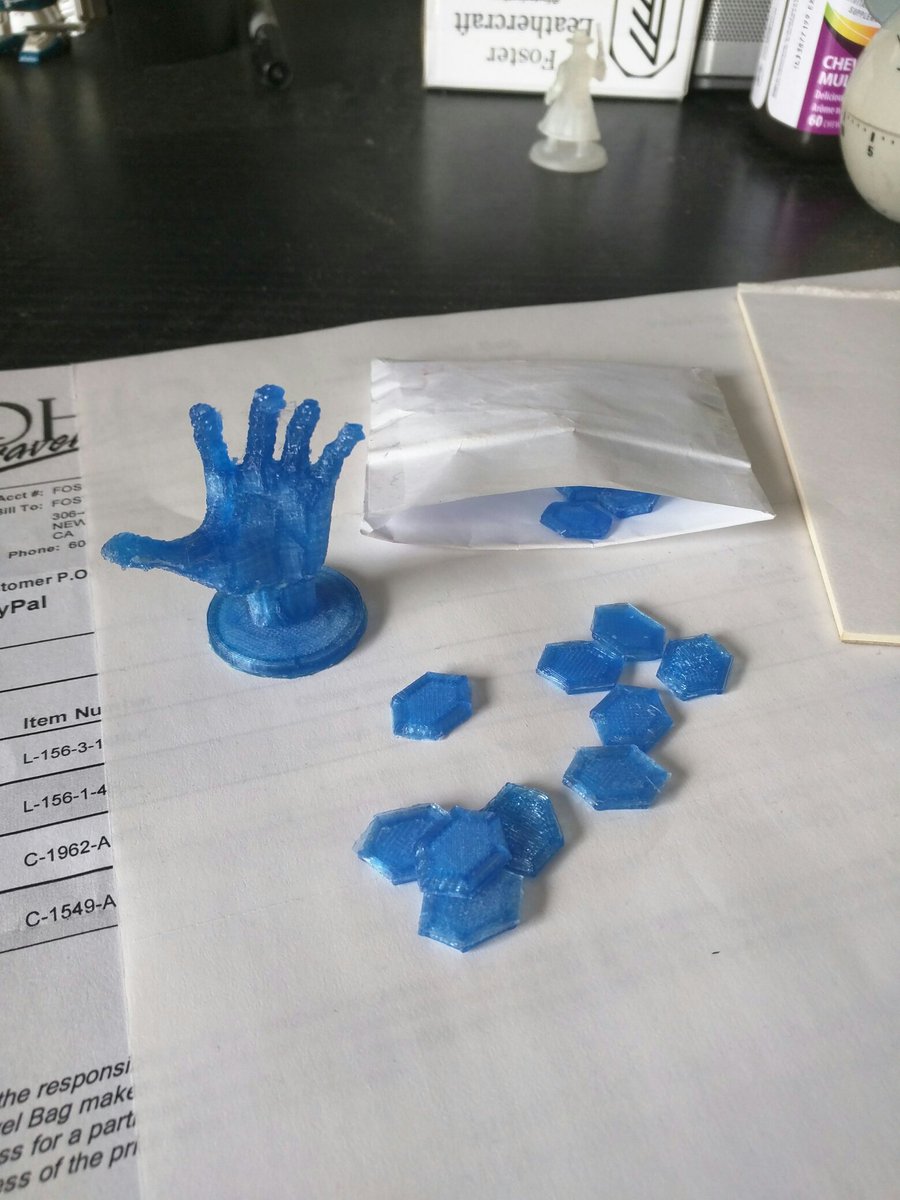

I tend to take pics of everything I make (as much for my own reference as anything) so I can give some photographic examples of what I meant. My first attempts at prints right after my printer arrived. I was an absolute layman and so nothing was coming out.   My first successful print (took a few weeks to manage this much)  This was the first model I'd made and successfully printed. It's a small model of a castle where my players were going to be spending a lot of time. What you don't see in this picture are the ~8 failed prints and weeks of tweaking it took to get this one.  My best attempt at printing a dragon for a boss fight. I might be able to get a cleaner print now but given the complicated modeling and ~36 hour print time I haven't been inclined to try.  Heroforge plastic mini, unpainted  Heroforge resin mini, unpainted   Some oozes I was able to model and print at different scales  A Bigsby Hand and Hero Points that I've been printing. I've been working on a line of spell effect minis and markers that I can add to my shop but it's been slow going with a lot of RL stuff I've had going on this year.  |

|

|

|

Post by joatmoniac on May 21, 2016 16:42:51 GMT

Amazing and comprehensive posts! Thanks for being my "someone else's 3D printer" haha. Your story mimics most things I was thinking. Doable with a cheaper one, but needs some tlc to get there. Or you could just pay for a bigger better printer.

|

|

|

|

Post by Tesla Ranger on May 21, 2016 21:59:34 GMT

You could go with a bigger, better printer but I'd suggest two things to keep in mind:

A) A lot of the "tlc" has to do with how the model is arranged and the print configured. A fair amount of know-how will always be required regardless of the quality of the printer. These things can be learned but there aren't really any quick or easy ways to learn them. For any one problem you could run into there tends to be a dozen possible causes. So you can't just google "bad print" and get a quick answer. It's quite possible that at some point there will be some new advance in the software (probably not the hardware) that significantly reduces the amount of know-how required but I haven't seen anything like that on the horizon.

B) There's a cost:benefit analysis to be considered. How many high-quality minis would you before it became more expensive to order them from HeroForge than to buy a $3000 Makerbot? My back-of-the-napkin math suggests that the break even point for resin figures (including shipping) would be about 75 minis. That doesn't include the cost of filament (typically $30-50 for a 1kg spool) which might tack on a few hundred on top of the printer price.

I expect the prices on printers and filament to continue to slowly decrease over time and the software will keep improving. I wouldn't be surprised if there were a practical home printer in another 10 years or so, but I also wouldn't be surprised if there wasn't one.

|

|

|

|

Post by Tesla Ranger on May 24, 2016 17:29:53 GMT

Somewhat tangentially related, I just painted a "High Resolution" mini from HeroForge yesterday. So here's a side-by-side of a low-fi (right) and hi-fi (left) minis post painting. They're just painted with your basic acrylic paints and no primer but it seems to be adhering perfectly well. The biggest difference is the advertised resolution.  |

|

|

|

Post by dmsam on Jul 18, 2018 3:40:13 GMT

I very recently started to dabble in 3D modeling and printing. HEAVY starting investment, but. . . is it worth it? Not sure! Why don't you guys help me decide?

Step 1: Sculpt a miniature. Use whatever 3D modeling program you want. Since I have no formal artistic training, this step took 20+ hours. If you are not feeling too creative, there are plenty of downloadable files from which you can print. In which case, skip this step.

Step 2: Make a viable .OBJ or .STLfile that a 3D printer can use. Some files may need editing, which includes patching holes, fixing geometry, etc. If you are lucky, your slicer program MIGHT do that for you.

Step 3: Get a 3D printer. For miniatures, SLA (stupidly expensive) or DLP (less stupidly expensive) printers work the best. These printers use UV cured resin as base materials, and print at ridiculously high resolutions (50 microns or less). For lower resolution prints or large volume prints (terrain, castles, battle-maps), extrusion printers that use plastic filaments might be more cost effective. Either way, this is where the big bucks go.

Step 4: Load the .OBJ or .STL into a slicer program (most printers come with one), which determines the orientation in which the model will print. Toying with supports will require the most time here. Supports are the extra materials upon which new layers can print/build on. More supports would mean more post-print work, and less supports could mean a higher chance of catastrophic print failure. For the model above, most of the supporting material is attached to its belly/underside (a design flaw, which I'll explain later).

Step 5: Print. Wait for a few hours and keep hoping nothing goes wrong.

Step 6a: WEAR GLOVES AND EYE PROTECTION. Remove the printed model from the printer in its partial glory. Resin printed parts will require a bath in 99% IPA to clean off any uncured resin. This stuff is toxic goop, and will leave a mess everywhere, so old newspaper on the floor might help. Once the model is clean, take out your handy crafting tools. . .

Step 6b: With your disposable gloves and eye protection still on, remove a HULKING MASS of supports as thin as 0.6mm VERY CAREFULLY with clippers, files, blades, etc. High DEX helps. This step could be as easy as ripping off a band-aid to being an hours-long task. Note that small blemishes will appear where the supports are removed, which will require more polishing later. If you break your resin-printed model during this step, there are ways to fix it! Simply dip a sacrificial paintbrush into the uncured resin, paint over the surface of the break, put the pieces together, then shine a UV light on it. The resulting bond should be as strong as the rest of the model, and nigh invisible.

With some beginner's luck and an hour of work, the model is almost done! As for the design flaw mentioned in Step 4, here's why: each of the bony protrusions on the lizardman's chest required individual supports, all of which made an inscrutable mess. Each connect point had to be manually clipped and twisted off with care, risking damage to any delicate structure/detail (as seen on the underside of the model). Alternatively, the model could be printed from the top-down perspective, which would require a support for each its MANY dorsal spines. Ain't nobody got time for that! So, if you decide to make your own model, or download some from the internet, be mindful of where the supports would go. There are more advanced tricks to avoid this particular situation, but not for my first print.

This is what we get after 20+ hours of sculpting, 3-5 hours of pre-printing preparation, and 1+ hour of post-print work. That's a US $.25 coin next to the printed model for scale. My cellphone camera won't even pick up all the details! Every spine on the lizardman's back printed perfectly. Even the teeth on the dinosaur-jaw club printed, and they measured at less than 0.3mm!

Step 6: For models printed with a resin-based printer, post-curing is usually necessary, which basically solidifies the model into a hardened form. This involves "baking" the printed model under direct sunlight or UV light for 15-60 min (depending on the material). WEAR APPROPRIATE EYE PROTECTION. Some artists may suggest doing this step before removing the supports, which will keep the tools cleaner and safer from the toxic, uncured resin. The drawback is that the supports become much harder to remove. Either way, after this, the resin becomes rock solid.

Step 7: Clean up the model with sandpaper, files, etc. Then, put a layer of opaque primer on it, which protects it from further unwanted UV radiation (ie: daylight) which will damage the resin over time. If the model isn't ready for a primer, store it in a cool, dark place.

After that, treat it like any other mini. The end!

|

|

|

|

Post by jamesfitts on Sept 29, 2020 4:06:31 GMT

3D printers are the future of printing technology. A couple of years ago, no one knew anything about 3D printing. However, things are dramatically changing, and people know a lot about 3D printing. There’s more to printing off a miniature than just popping the material in and waiting for your perfect little figure to come out. But even if you’re just getting started printing your very own 3D miniatures, the good news is that there are plenty of printer choices. Whether you are looking for prototypes for a design model, role-playing games, tabletop games, or video gaming miniatures for concept art, there are some better printers for miniatures.

5 Best 3D Printers for Miniatures

1.ANYCUBIC Photon UV – Editor’s Choice 2.ELEGOO Mars UV – Best for D&D Minis 3.Comgrow Creality Ender 3 Pro – Best for Beginner 4.Ultimaker 2+ 3D Printer – Best but Expensive 5.Sindoh 3DWOX DP200 – Best Value for Money

Read more information about these 3D Printers for Miniatures. |

|

|

|

Post by wilson6798 on Nov 30, 2020 16:23:29 GMT

If you are planning to create some custom miniature models then it will be better if you choose the Best 3D Printers for Miniatures. But the question is, which printer should you choose? The answer is simple, you have to go for the best. It is true that different manufacturers produce different models of this printer, but as a rule, they all promise to create the best miniature models. When you go shopping for the best printer, make sure that you look at all the different models. You can easily check out the different models online by visiting different websites. Here, you will find a lot of information related to the different models. So you will not only know what features are good and what is bad in the different models, but you also get to know about the price range, features, and other important facts related to the model you are buying. |

|